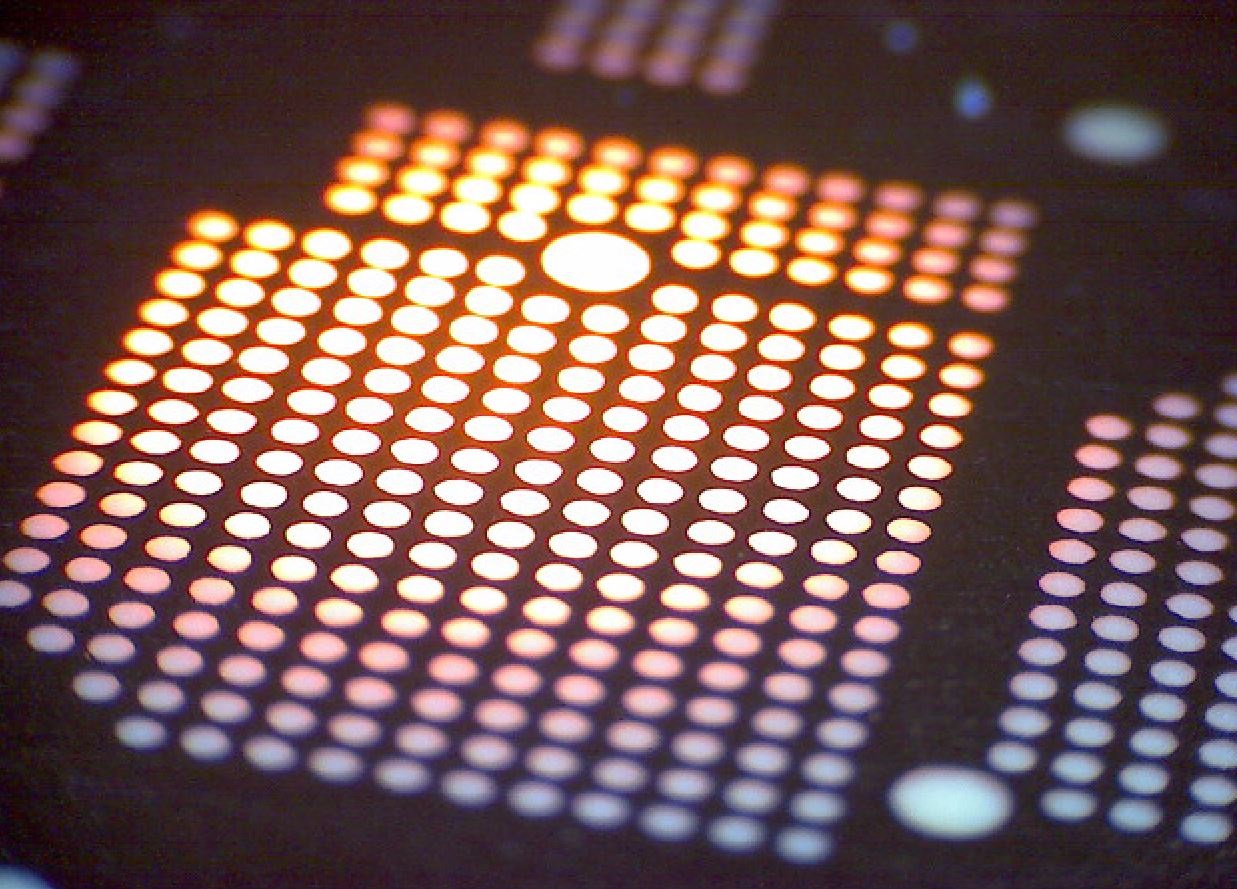

In the field of via filling, Peters is setting an exclamation mark with ELPEPCB® PP 2794. The thermal curing via filler enables bubble-free and even hole filling and the subsequent application of planar insulation layers or metallization, especially in the vacuum plugging process.

No cracks or delaminations

”The paste shows excellent metallisability and no cracking or delamination,” says the head of R&D, Detlev Schucht (photo), describing the benefits of the paste. The Peters product enhances the reliability of the printed circuit board. The solvent-free, 1-component system characterised by a long processing time is available both in cartridges and large containers and, according to Detlev Schucht, makes application simple and economical. The adjusted flowability permits the filling of “thick” PCBs with higher aspect ratios.

When developing this paste, special attention was paid to achieving the highest possible glass transition temperature (Tg) along with low coefficients of thermal expansion (CTE). Thus, thermomechanical analysis (TMA) in tensile mode yields a Tg of 158°C and a CTE of 25/106 ppm (α1/α2). In the expansion mode, the Tg is 151°C while the CTE reaches 23/72 ppm (α1/α2).

Via Filler has been developed sustainably in the Peters laboratory

“With ELPEPCB® 2794, a modern and efficient via filler ‘Made in Germany’ is launched that is available worldwide without any problem and complies with RoHS requirements,” reports Sven Kramer, head of Application Technology at Peters. This way, Peters also complies with the sustainability principle. “With our new plugging paste, the customer can be assured that the proportion of hazardous substances that are harmful to the environment and sometimes difficult to dispose of is limited to the maximum permitted,” says coatings engineer Sven Kramer.

#plugging